Oracle Apps Inventory – Defining Cycle Count, Location and Unit of Measure

Cycle Count

Responsibility: Inventory, Vision Operations USA

1. (N) Counting > Cycle Counting > Cycle Counts

2. (B) New

3. Enter the following cycle count information.

- Name: FGI Cycle Count

- Description: Finished Goods Cycle Count

- Calendar: Vision01

- Adjustment Account: Miscellaneous

- Late Days: 1

- Starting Sequence: 0

- Unscheduled Entries: Selected

- Display System Qty: Selected

4. Select Specific in the Count Subinventories alternative region.

5. Select the FGI subinventory from list of values.

6. (T) Serial and Schedule

7. Enter the following Serial and Schedule information:

- Auto Schedule: Yes

- Frequency: By period

8. (T) Adjustments and ABC

9. Enter the following approval tolerances:

- Qty Variance: 3

- Adjustment Value: 50

- Hit / Miss Analysis: 10

10. Enter the following ABC Information:

- Group: Finished Goods ABC

- Option: (Re)initialize

11. (B) Classes.

12. Enter the following ABC Class information:

- Class: Finished Goods A

- Count: 150

- Class: Finished Goods B

- Count: 100

- Class: Finished Goods C

- Count: 50

13. (M) File Save.

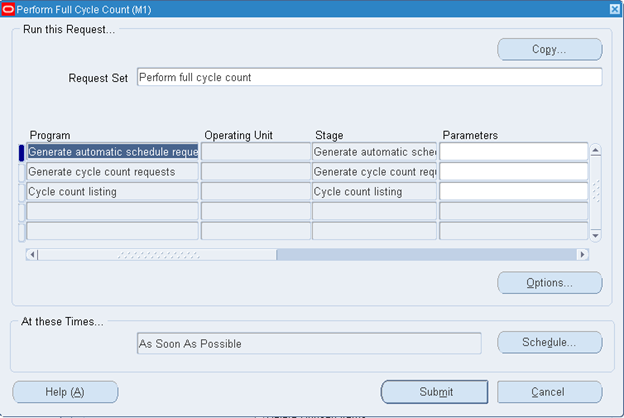

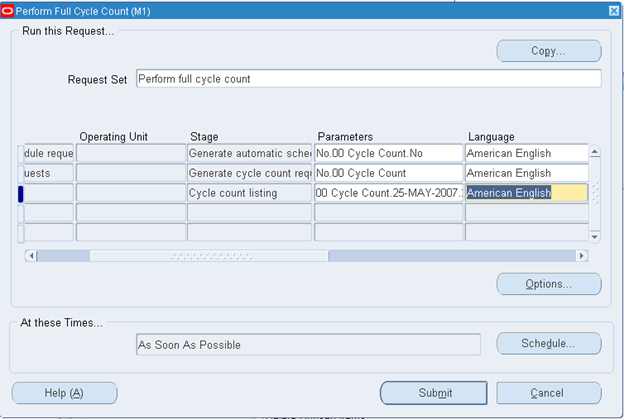

14. (M) Tools > Perform Full Cycle Count

15. Enter the cycle count name for the following parameters

- Generate automatic schedule recount

- Generate cycle count request

- Cycle count listing.

16. (B) Submit.

17. (M) File > Close Form.

Entering Cycle Count Entries Using a Mobile Device

Instructor Note: You must have access to a telnet session to run the mobile emulator. Use the up and down arrows to navigate.

If you are in an education center, verify you are logged in to the launch pad.

18. Start the Telnet session.

- Windows Start menu > Run

- Enter telnet esxxxx.oracle.com 7070 in the Run dialog box, where xxxx is the instance number.

19. Select <Default> from the Device List.

20. Enter your user name and password. Note that Materials & Mfg responsibility must be assigned to your user name.

21. Select <Materials & Mfg>

22. Select <Inventory>

23. Select <Counting>

24. Select <Cycle Count>

25. Select <Normal>

26. Enter the following cycle count information:

- Org Code: M1

- Cycle count name: FGI Cycle Count

- Subinventory: FGI

- Item: AS18947

- Quantity: Enter a number plus or minus the system quantity.

27. Select <Done>

Cycle Count Entries and Approvals

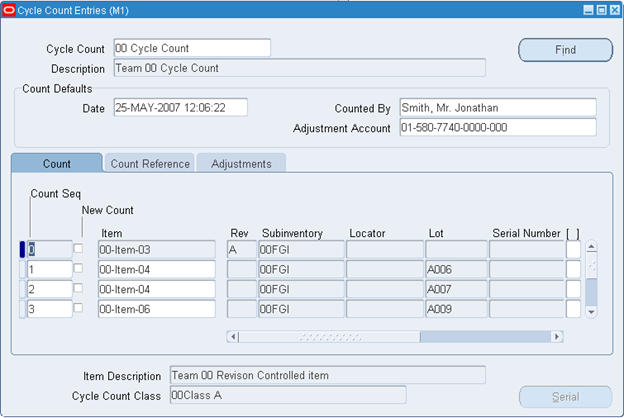

28. (N) Counting > Cycle Counting > Cycle Count Entries

29. Enter FGI Cycle Count in the Cycle Count field.

30. Choose find.

31. At the question: “Find all open count requests?” choose Yes to view all open cycle count items.

Note: Notice the item amount entered during the mobile counting demonstration does not appear.

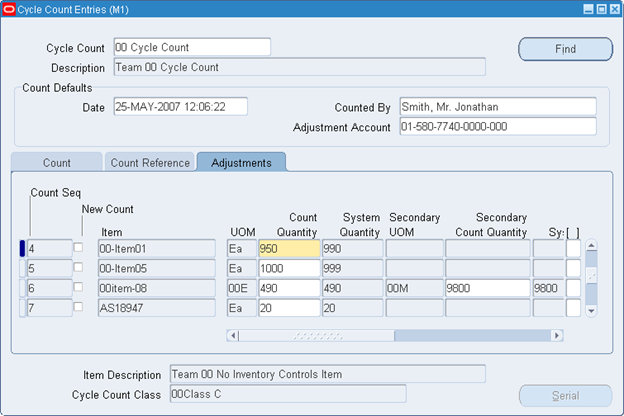

32. (T) Adjustments.

33. Enter the count quantities.

34. (M) File > Save.

35. (M) File > Close Form.

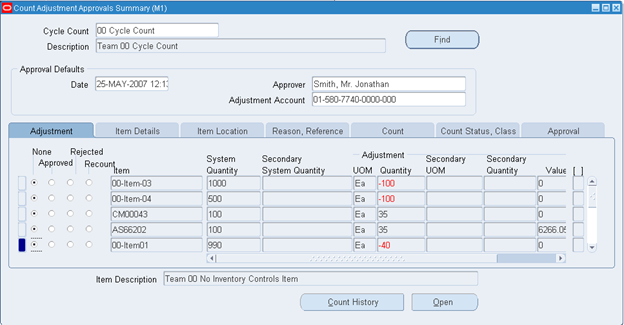

36. (N) Counting > Cycle Counting > Approve Counts

37. Enter FGI Cycle Count in the Cycle Count field.

38. (B) Find.

39. At the question: “Query count pending approval only?” choose Yes to view all that require approval.

Note: Notice the item quantity entered in the mobile counting demonstration appears in the Count tabbed region.

40. Choose Approved to approve an item adjustment.

41. Select the Approver from the drop down list in the Approval tabbed region.

42. (M) File Save.

43. (B) OK.

44. Close the Approvals window.

45. Approve or reject the remaining items.

46. (M) File > Save.

47. (M) File > Close Form.

Practice – Performing a Cycle Count

Overview

In this practice you will perform a cycle count using the ABC compile group you created in a previous lab.

Assumptions

- You are skilled in Oracle Navigation.

- You completed the Compile an ABC Analysis practice.

- You completed the Define Items practice.

- You have at least 20 items in your ##FGI subinventory.

Instructor Note: (Suggestion: Create an ABC Compile for ‘FGI’ and use it instead of ##FGI)

- You must have access to an Oracle Application Vision database or comparable training or test instance at your site on which to complete this practice.

Responsibility: Inventory, Vision Operations USA

Tasks

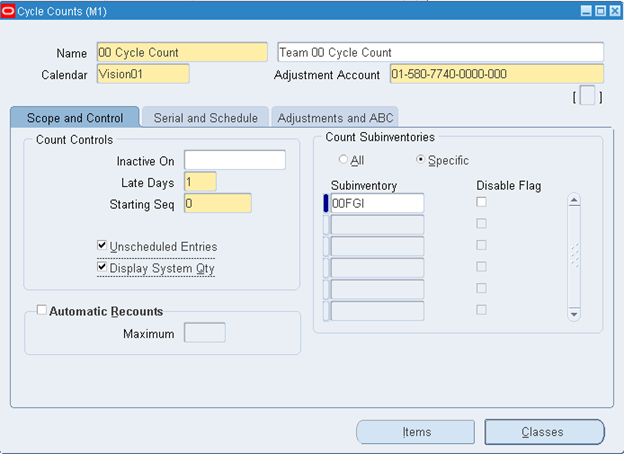

Define a Cycle Count Header

Define a cycle count header using the following information:

- Name: ##Cycle Count

- Description Team ##Cycle Count

- Adjustment Account: Miscellaneous

- Late Days: 1

- Starting Sequence: 0

- Unscheduled entries Yes

- Display System qty: Yes

- Count Subinventories: Specific

- Subinventory: ##FGI

- Auto Schedule: Selected

- Frequency: By Period

- Approval Required: If out of Tolerance

- QTY 3%

- Adjust Value: 50

- Hit/Miss: 10%

- Group: ##ABC Group

- Option: (Re)initialize

- Class A: 150 counts per year

- Class B: 100 counts per year

- Class C: 50 counts per year

Perform a Cycle Count

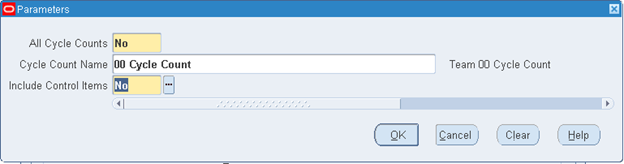

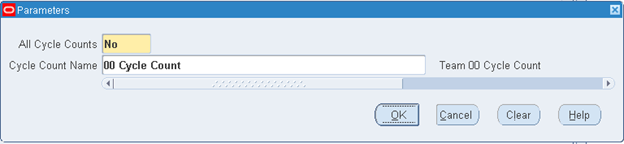

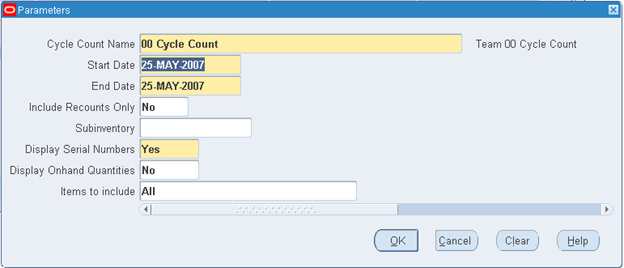

Use the following parameters to perform a cycle count:

- Name: Generate Automatic Schedule

- Cycle Name: ##Cycle Count

- Name: Generate Cycle Count Requests

- Cycle Name: ##Cycle Count

- Name: Cycle Count Listing

- Cycle Name: ##Cycle Count

Enter Cycle Count Entries

View the system quantities and enter quantities for the cycle count. Have some of the items out of tolerance, and have at least one item match the system quantity.

Approve, Reject or Recount Cycle Count

Why are some of the items already approved? ________________________________________

Approve, Reject or recount all entries for your cycle count.

Solution – Performing a Cycle Count

Define a Cycle Count Header

Responsibility: Inventory, Vision Operations USA

1. Navigate to the Cycle Counts window.

- (N) Counting > Cycle Counting > Cycle Counts

2. (B) New

3. Enter a new cycle count header using the following information:

-

(T) Scope and Control

- Name: ##Cycle Count

- Description Team ##Cycle Count

- Calendar: Vision01

- Adjustment Account: Miscellaneous

- Late Days: 1

- Starting Sequence: 0

- Unscheduled Entries: Select

- Display System Qty: Yes

- Count Subinventories: Specific

- Subinventory: ##FGI

- Name: ##Cycle Count

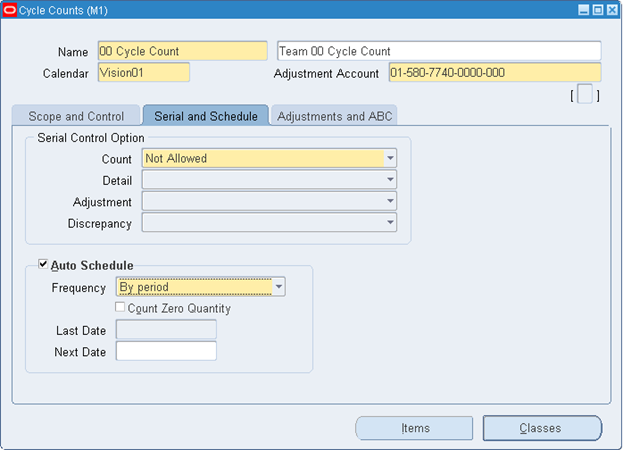

-

(T) Serial and Schedule

- Count: Not Allowed

- Auto Schedule: Selected

- Frequency: By Period

- Count: Not Allowed

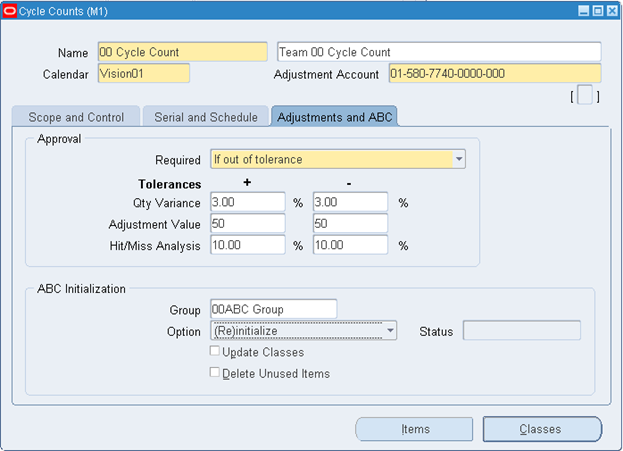

-

(T) Adjustments and ABC

- Approval Required = If out of tolerance

- Qty Variance = 3%

- Adjustment Value = 50

- Hit/Miss = 10%

- Group = ##ABC Group

- Option = (Re)initialize

- Approval Required = If out of tolerance

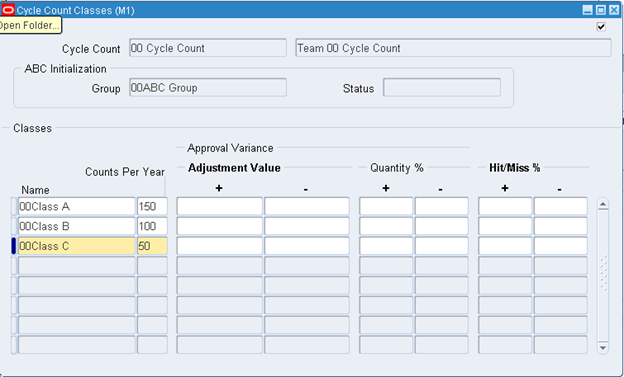

-

(B) Classes

- ##Class A = 150 counts per year

- ##Class B = 100 counts per year

- ##Class C = 50 counts per year

- ##Class A = 150 counts per year

4. (M) File > Save

5. (B) OK

Perform a Cycle Count

6. (M) Tools > Perform Full Cycle Count

7. Enter the following parameters. After entering each parameter, click OK.

- Generate automatic schedule (Parameters field): ##Cycle Count

- Generate cycle count requests (Parameters field): ##Cycle Count

- Cycle Count Listing (Parameters field): ##Cycle Count

8. (B) Submit

9. (B) OK

10. (M) File >Close Form

Note: Do not proceed until after your concurrent request completes.

Enter Cycle Count Entries

11. Navigate to the Cycle Count Entries window.

- (N) Counting > Cycle Counting > Cycle Count Entries

12. Enter ##Cycle Count in the Cycle Count name field, or select your cycle count from the list of values.

13. (B) Find

14. (B) Yes

15. (T) Adjustments

16. Enter Count quantities for your items. Enter a few quantities that are out of tolerance, a few quantities within tolerance, and at least one that matches the system quantity.

17. (M) File > Save

18. (M) File > Close Form

Approve, Reject or Recount Cycle Count

19. Navigate to the cycle count approvals window.

- (N) Counting > Cycle Counting > Approve Counts

20. Select your cycle count from the LOVs in the Cycle Count field.

21. (B) Find

22. (B) No

23. Why are some of the items already approved? They fall within set approval limits.

24. Approve, reject or recount your items.

25. (B) Save

26. (B) OK

27. (M) File > Close Form

Guided Demonstration – Setting up Locations

Responsibility: Inventory, Vision Operations USA

1. Navigate to the Locations window.

- (N) > Setup > Organizations > Locations.

2. Define a Location using the following information:

- Name: M12 Orlando

- Description: Orlando Manufacturing

3. (T) Address Details

- Address Style: United States

4. Enter the following address information:

- Address Line 1: 100 Buena Vista Drive

- City: Orlando

- State: FL

- Zip Code: 32803

- County: Orange

- Country: United States

- Telephone: (407) 828-5000

5. (B) OK

6. Select the following Timezone from the list of values:

- Eastern Time

7. (T) Shipping Details

- Ship-To Location: M12 Orlando

8. Verify the following boxes are checked

- Ship-To Site

- Receiving Site

- Office Site

- Bill-To Site

- Internal Site

9. Save and Close form.

Unit of Measure Conversions

Responsibility: Inventory, Vision Operations USA

1. (N) Setup > Units of Measure > Conversions

Note: The application prompts you to select an organization if it is a first-time access to the database. Select M1 Seattle Manufacturing from the list of values.

2. (M) File > New

3. Enter 00-Centimeter in the Unit field.

4. Enter 0.01 in the Conversion field.

5. (M) File > New

6. Enter 00-Kilometer in the Unit field.

7. Enter 1000 in the Conversion field.

8. (M) File > Save

9. (M) File > Close Form